BNSF联合西屋制动打造100%纯电池货运电力机车 可与内燃机车重联构成混合动力机车组

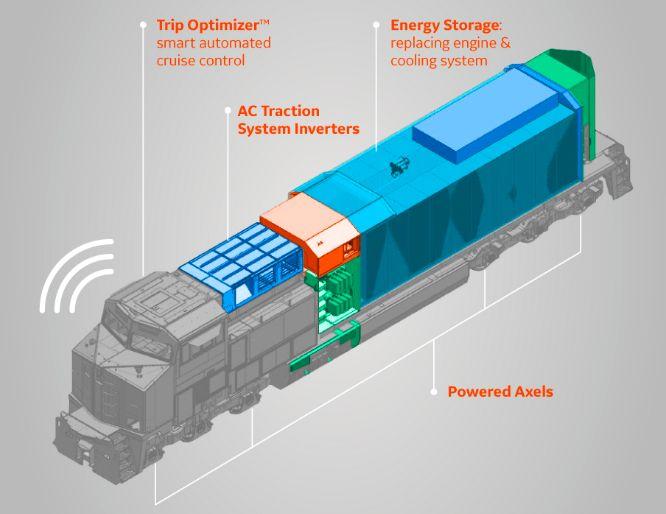

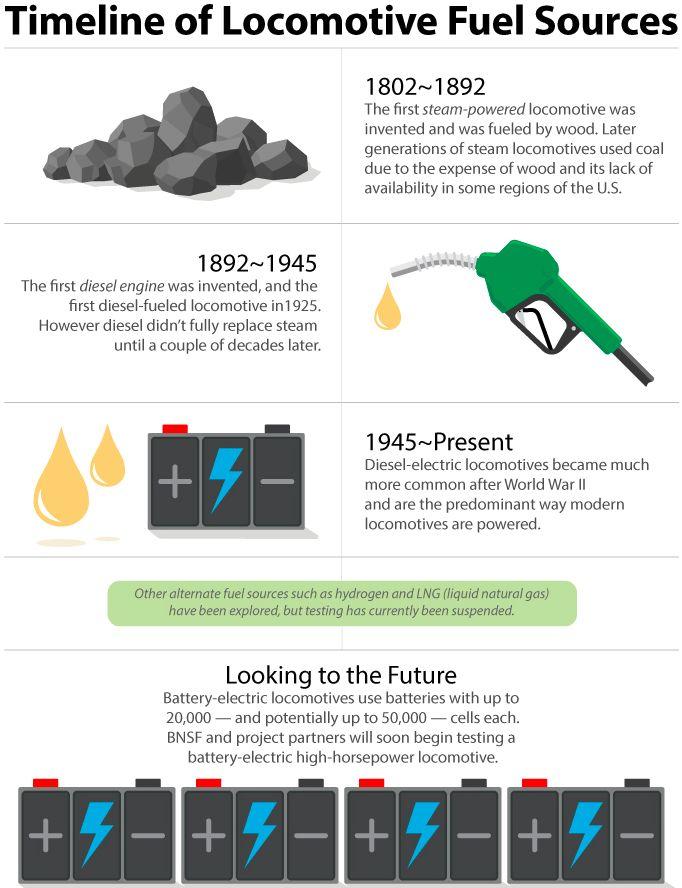

BNSF联合西屋制动打造100%纯电池货运电力机车 可与内燃机车重联构成混合动力组 BNSF和项目合作伙伴西屋制动(Wabtec)正在开发并将很快开始测试电池动力大功率货运机车,BNSF和其他铁路公司多年来一直在铁路货场试制电池动力电力机车,但功率较低,主要用于铁路货车调车。 注:BNSF为巴菲特旗下伯克希尔的子公司,运营北美最大的铁路货运网。 BNSF新技术高级经理Michael Cleveland表示:“现在电池的不同之处在于,它们的功率比以前大得多,而且供应商已经提高了电池的质量、可靠性和技术,因此我们能够测试公路机车的功率。”正在搜索技术。 2018年,BNSF和GE Transportation(GE运输板块后被西屋制动合并)联手开发了一款100%电池动力货运机车原型,该原型可与传统内燃机车协同工作,形成电池动力混合动力组。(此处组是指两个或多个机车耦合重联在一起的情况。)混合动力车的型式试验预计将于2020年底开始。 作为零排放和近零排放货运设施项目的一部分,该项目得到了加州空气资源委的资金扶持。一旦所有的设备和相关支撑系统就位,计划在加州斯托克顿和巴斯托之间大约350英里线路上进行测试。 一旦完全开发,电池电力机车将提供环境效益和节省燃料的整个机车组成。在铁路堆场内,该系统将关闭或闲置其他机车(如果可能的话),并使用电池电力机车,以减少当地的排放和噪音。一旦上了路,机车将在幕后工作,以确定最佳的方式使用电池的动力。由于这一功能,火车行驶在开阔地带时,该系统还可以选择“掠食”电池,从而节省数百加仑的柴油。

电池电力机车一旦全面发展,将为整个机车组提供环境效益和燃油节约。在铁路站场,列车组将关闭或“惰行”其他机车(如有可能),仅使用蓄电池电力机车来减少排放和噪音。一旦上路,机车将根据运用场景以确定使用电池动力的最佳方式。借助这种能力,当列车在开阔的地面上行驶时,列车组还可以选择“蹭”电池动力,从而节省数百加仑的柴油。 在接下来的几年里,BNSF和Wabtec希望研究如何建造、配置、运用和维护电池电力机车。就像从蒸汽机车向柴油电力机车的转变一样,完全装备电池动力列车也需要数年的时间。 “有望成为行业规则的改变者,特别是随着技术的不断成熟,”Wabtec的北美机车高级产品经理DanMcNair说。“我们在加州与BNSF的示范项目将使我们对电池动力的能力以及利用该技术的最佳和最安全的操作方法积累深刻洞察力。柴油动力加电池的智能化利用可以提供多重运营效益,我预计电池动力机车的普及将在未来十年内发生。” BNSF的原型机车将使用类似于电动汽车引擎盖下的电池,锂离子储能装置,包含镍钴锰组合,然而在尺寸和密封方面,它的规格完全不同。

考虑到一个标准的电动汽车电池组通常可以容纳几百个电池芯——每个芯的大小都和笔记本的差不多。这台机车样车将有一个大约2万个电池芯,未来的版本可能会有多达5万个电池芯。这些电池还必须能够经得住机车的重载环境。此外,从外观上看,电池动力机车与柴油动力机车也并无太大不同。 在机车的试点测试开始之前,今年晚些时候需要在BNSF位于斯托克顿的站场设计并安装电池充电设备。斯托克顿充电站将提供初始充电,而新机车将在制动时提供再生动力,以扩大其行驶范围。 Cleveland解释说:“电池将通过动力制动回收能量(动力制动dynamic braking是行驶中的列车动能可通过机车牵引电机转化为电流),与今天的柴油机车不一样,从本质上讲,每次动力制动时可减速和控制列车,并给电池将再充电”。 这款由电池供电的机车还将使用高级版的列车能量管理软件,来检查前方的路线,并计算如何最佳利用电池来降低燃料消耗。 BNSF环境部副总裁John Lovenburg说:“我们现在正在开发和测试‘下一代’火车头,以建立我们相对于长途卡车的优势,保持竞争力,降低运营成本。” 这将是引领铁路行业未来的一个发展方向。BNSF LEADS THE CHARGE ON TESTING BATTERY-ELECTRIC LOCOMOTIVEBNSF and project partners are developing and will soon begin testing a battery-electric high-horsepower road locomotive (the type that moves freight trains from Point A to Point B). BNSF and other railroads have tested low-horsepower battery-electric locomotives in rail yards for years, but mainly for switching freight cars.“What’s different about today’s batteries is that they are significantly more powerful than before, and manufacturers have improved battery quality, reliability and technology so we’re able to test their power for our road locomotives,” said BNSF’s Michael Cleveland, senior manager, Emerging Technologies.In 2018, BNSF and Wabtec (formerly GE Transportation) joined forces to begin developing a 100-percent battery-electric road locomotive prototype that works with conventional diesel locomotives to make a battery-electric hybrid consist. (Consist refers to when two or more locomotives are coupled together.) Performance testing of the hybrid is expected to begin in late 2020.The project is being supported by a grant from the California Air Resources Board as part of its Zero- and Near Zero-Emission Freight Facilities program. Once all the equipment and support systems are in place, the plan is to run tests between Stockton and Barstow, California – about 350 miles.Once fully developed, the battery-electric locomotive will provide environmental benefits and fuel savings for the entire locomotive consist. While in the rail yard, the consist will shut down or idle the other locomotives (when possible) and use the battery-electric locomotive to reduce local emissions and noise. Once on the road, the locomotive consist will work behind the scenes to determine the best way to use the battery power. Thanks to this capability, the consist could also choose to “graze” on battery power when the train is cruising through open landscape, saving hundreds of gallons of diesel.Over the next few years, BNSF and Wabtec expect to learn much about how to build, configure, operate and maintain a battery-electric locomotive. Like the transition from steam to diesel-electric locomotives, it will take years to support an all battery-electric fleet.

“It certainly has the potential to be a game changer, especially as the technology continues to mature,” said Wabtec’s Dan McNair, senior product manager for North American Locomotives. “Our demonstration project in California with BNSF will give us tremendous insight into the capabilities of battery power, as well as the best and safest operational methods of leveraging the technology. Smart utilization of the batteries with diesel power can provide multiple operational benefits, and I expect the proliferation of battery locomotives will happen over the next decade."BNSF’s prototype locomotive will use a battery cell similar to what you might find under the hood of an electric car. It is a lithium-ion energy storage unit with cells that contain a combination of nickel, manganese and cobalt. In terms of size and packaging, however, it’s on a totally different scale.Consider a standard electric car battery usually holds a few hundred storage cells — each around the size of a mini-tablet computer. The locomotive prototype will have a battery with approximately 20,000 cells, and future versions may have as many as 50,000 cells. The cells also must be able to weather the heavy-going environment of a locomotive. From the outside, the battery-powered locomotive won’t look much different from its diesel counterparts.Before the pilot testing of the locomotive can begin, a battery charger will need to be designed and installed at BNSF’s Mormon Yard in Stockton later this year. While the Stockton battery charging station will provide an initial charge, the new locomotive will be designed to provide regenerative power under braking to extend its range.“The battery will recover energy through dynamic braking,” Cleveland explained. (Dynamic braking is where the kinetic energy of a moving train is used to generate electric current at the locomotive’s traction motors.) “Essentially, every time dynamic braking is used to slow and control train speed, the battery will refill its energy reserves, which is unlike anything today’s diesel-powered locomotives can do.”The battery-electric locomotives will also use an advanced version of train energy management software to look at the route ahead and calculate how to best use the battery to reduce fuel consumption. “We're developing and testing the ‘next-generation’ locomotive now to build our advantage over long-haul trucks, remain competitive and reduce our operating costs,” said John Lovenburg, vice president, Environmental, BNSF.And together, with our project partners, we’ll be leading the “charge” in railroading’s future.